Introduction to Customization in Manufacturing

In today’s competitive manufacturing landscape, customization is not just a luxury; it’s a necessity. Tailoring components to meet specific factory needs can significantly enhance efficiency, functionality, and product longevity. This article delves into the world of drawer slides, a seemingly minor component that plays a pivotal role in various applications, and explores how customization can transform this essential hardware into an optimized solution for your factory.

Understanding Drawer Slides

Understanding the intricacies of drawer slides is crucial for anyone involved in product design, manufacturing, or even home improvement projects. These components may seem minor, but they play a significant role in the functionality and user experience of cabinetry, furniture, and industrial equipment. Let’s delve deeper into the types of drawer slides available and the importance of customization.

Types of Drawer Slides

Drawer slides are categorized based on their mounting type, mechanism, and material, among other factors. Here’s a closer look at some common types:

Ball Bearing Slides: These slides use ball bearings to ensure smooth movement. They are durable and can handle heavy loads, making them suitable for various applications, from office furniture to industrial machinery.

Under-Mount Slides: Installed beneath the drawer, these slides offer a clean look as they are not visible when the drawer is open. They are typically used in high-end cabinetry and furniture where aesthetics are as important as functionality.

Side-Mount Slides: These are mounted on the sides of the drawer and cabinet. Side-mount slides are versatile and come in various weight capacities, but they reduce the width of the drawer slightly.

Center-Mount Slides: A single slide mounted under the drawer’s center. These slides are less visible than side-mount slides and are often used in traditional furniture designs.

Soft-Close Slides: These slides include a mechanism that slows down the drawer before it closes, preventing slamming. They enhance the user experience by ensuring smooth and quiet operation.

Push-to-Open Slides: Ideal for modern, handleless designs, these slides allow a drawer to open with a simple push, eliminating the need for external handles or knobs.

Importance of Customization

Customization plays a pivotal role in optimizing drawer slides for specific applications. Here’s why customization is critical:

Enhanced Performance: Custom slides can be designed to meet the application’s exact weight capacity and durability requirements, ensuring optimal performance and longevity.

Specific Requirements: Whether it’s a need for extreme temperature resistance in industrial environments or corrosion resistance in marine applications, customization allows for slides to be tailored to specific conditions.

Addressing Unique Challenges: Every project has challenges, from space constraints to unique operational requirements. Custom drawer slides can solve these challenges by fitting precisely into the design, enhancing functionality and aesthetics.

Innovation and Design Flexibility: Customization encourages innovation, allowing designers to experiment with materials, mechanisms, and features like integrated locks or electronic controls, pushing the boundaries of what’s possible in drawer design.

In conclusion, understanding the different types of drawer slides and the importance of customization can significantly impact the success of a product. Manufacturers and designers can create products that meet and exceed expectations regarding functionality, design, and user experience by choosing the right kind of slide and opting for customized solutions when necessary.

Customization Options for Drawer Slides

Customizing drawer slides involves several considerations, each of which plays a crucial role in the drawer’s overall functionality and user experience. Let’s delve deeper into the customization options available for drawer slides, highlighting the importance of material selection, size and load capacity, mounting options, extension and retraction mechanisms, and unique features.

Material Selection

The choice of material for drawer slides is fundamental, impacting not only the durability and longevity of the slides but also their suitability for specific environments. Here are some common materials:

Stainless Steel: Known for its strength and corrosion resistance, stainless steel is ideal for use in harsh environments or where cleanliness is paramount, such as in medical or food preparation settings.

Aluminum: Lightweight yet strong also smooth, aluminum slides are suitable for applications where minimizing weight is crucial without sacrificing performance.

Plastic: For lighter loads and cost-sensitive applications, plastic slides offer a corrosion-resistant option with smooth operation.

Size and Load Capacity

Customizing drawer slides’ size and load capacity is vital to ensure they fit the designated space and can support the intended weight without failure. This customization allows for:

Tailored Fit: Ensuring the slides match the drawer’s dimensions for a seamless appearance and optimal functionality.

Appropriate Load Capacity: Select slides that can handle the weight of the drawer and its contents, from light-duty office supplies to heavy-duty industrial tools.

Mounting Options

The choice of mounting options influences both the installation process and the slide’s performance. Options include:

Side-Mount: A standard choice that is versatile and straightforward to install but may slightly reduce the drawer’s width.

Under-Mount: Providing a cleaner look by hiding the slides under the drawer, perfect for sleek, modern designs.

Top-Mount: Used in specialized applications where side or under-mount options are not feasible.

Extension and Retraction Mechanisms

The extension and retraction mechanism determines the drawer’s accessibility and ease of use. Options range from:

Full Extension: This allows complete access to the drawer’s contents, making it ideal for deep drawers.

Over-Travel: Extends beyond full extension, offering even greater access, especially useful in high-capacity storage situations.

Partial Extension: Limits how far the drawer can be opened, used in spaces where the full extension would be impractical.

Special Features

Incorporating special features can significantly enhance the functionality and user experience of drawer slides:

Soft-Close: Prevents drawers from slamming shut, reducing noise and wear on the drawer.

Push-to-Open: Eliminates the need for handles or knobs, offering a clean, minimalist look and easy operation.

Locks: Adds security for sensitive or valuable contents, ideal for file cabinets or personal storage.

By carefully considering these customization options, manufacturers and designers can create drawer slides that meet specific requirements, enhancing drawers’ performance, appearance, and functionality across a wide range of applications.

Integrating Custom Drawer Slides into Your Factory

Integrating custom drawer slides into your factory’s production line or specific products requires a holistic approach, encompassing design considerations, the manufacturing process, and rigorous quality assurance. Let’s explore these aspects in more detail to understand how they contribute to successfully implementing custom drawer slides.

Design Considerations

The initial phase in integrating custom drawer slides involves meticulous design planning. This stage is critical to ensure the slides are perfectly tailored to meet the application’s needs. Key design considerations include:

Understanding the Application: Knowing the end-use environment and how the drawer will be used is essential. This understanding helps select the appropriate material, load capacity, and type of slide mechanism.

Load Requirements: Accurately assessing the weight the slides need to support is crucial. This assessment ensures the slides are robust enough to handle the load without compromising performance or longevity.

Space Constraints: The available space influences the choice of slide type (e.g., side-mount, under-mount) and dimensions. Customization allows for precise fitment within the designated space, optimizing storage and accessibility.

User Experience: Considering how the drawer will be used can guide decisions on features such as soft-close mechanisms or push-to-open functionality, enhancing the overall user experience.

Manufacturing Process

The manufacturing process of custom drawer slides is intricate, requiring a high degree of precision and expertise. Steps in the process include:

Material Selection: Based on the design considerations, the appropriate materials are selected for durability, weight, and environmental resistance.

Fabrication: Cutting-edge manufacturing techniques, such as precision machining and laser cutting, fabricate the drawer slides according to the exact specifications.

Assembly: Components of the drawer slides are meticulously assembled, ensuring that all parts fit together seamlessly for smooth operation.

Finishing: Finishing processes, such as coating or anodizing, enhance corrosion resistance and aesthetics.

Quality Assurance

Quality assurance is a continuous process that spans the entire manufacturing cycle of custom drawer slides. It ensures that the final product meets the design specifications and adheres to the highest performance standards. Critical quality assurance practices include:

Inspection: Regular inspections are conducted at various stages of the manufacturing process to identify and rectify any defects or deviations from the specifications.

Testing: Drawer slides undergo rigorous testing, including load-bearing and cycle tests, to verify their durability and performance under real-world conditions.

Feedback Integration: Feedback from quality assurance processes is integrated into the manufacturing workflow, allowing for continuous improvement and refinement of the product.

Integrating custom drawer slides into your factory’s offerings involves a comprehensive approach, from initial design to final quality assurance. By adhering to these principles, manufacturers can ensure that their products meet the highest performance, reliability, and user satisfaction standards.

Case Studies

Exploring case studies of real-world applications highlights the transformative impact that customized drawer slides can have across various industries. These examples demonstrate the versatility and necessity of such customizations and offer valuable insights and inspiration for future projects. Let’s delve into a few case studies that showcase how tailored drawer slide solutions can address specific challenges and enhance functionality, efficiency, and user experience.

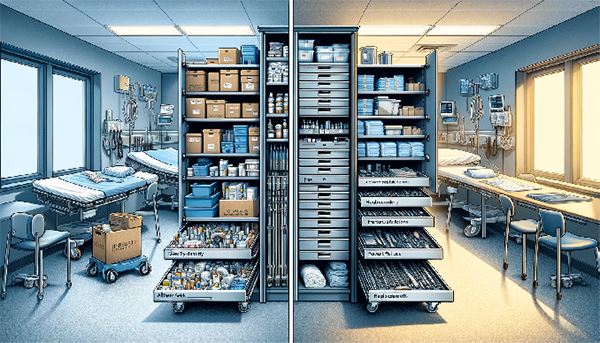

Case Study 1: Healthcare Industry – Hospital Storage Solutions

Challenge: A major hospital sought to improve the storage and accessibility of medical supplies in its emergency rooms. The standard drawer slides could not withstand the frequent use and heavy loads, leading to frequent failures and replacements.

Solution: Customized heavy-duty, full-extension drawer slides were designed and installed. These slides were made from high-grade stainless steel to ensure durability and ease of cleaning. A soft-close mechanism was also integrated to minimize noise in the sensitive environment.

Impact: The custom drawer slides significantly improved the efficiency and reliability of storage in the emergency rooms. Medical personnel could quickly and quietly access necessary supplies, enhancing care delivery. The durability of the slides also reduced maintenance costs and equipment downtime.

Case Study 2: Aerospace Industry – Aircraft Galley Storage

Challenge: An aerospace company faced challenges with optimizing storage space and ensuring the durability of drawer slides in aircraft galleys, where weight and space constraints are critical factors.

Solution: Lightweight aluminum drawer slides with a custom locking mechanism were developed to secure contents during turbulence. The slides were designed for full extension, maximizing space utilization and accessibility.

Impact: The customized drawer slides improved the functionality and efficiency of galley storage, enhancing the crew’s ability to serve passengers while complying with stringent aerospace standards. The weight reduction also contributed to overall fuel efficiency.

Case Study 3: Automotive Industry – Tool Storage in Service Centers

Challenge: Automotive service centers required a solution for storing heavy tools and equipment in a space-efficient way and easily accessible to technicians.

Solution: Customized drawer slides with high load capacities and over-travel extension were implemented in the tool cabinets. These slides were engineered to withstand the industrial environment and frequent access, incorporating features like corrosion resistance and easy installation.

Impact: The custom drawer slides transformed the service centers’ operations by enabling efficient tool storage and retrieval, reducing technicians’ time searching for tools, and increasing productivity. The durability of the slides also minimized the need for replacements, offering long-term cost savings.

Case Study 4: Retail Industry – Display Cabinets

Challenge: A high-end retail store needed a sophisticated solution for display cabinets that could enhance the shopping experience by providing smooth access to displayed items without compromising security.

Solution: Customized under-mount drawer slides with soft-close and push-to-open mechanisms were installed, offering a sleek, handle-free design that complemented the store’s aesthetic. The slides were also equipped with integrated locks for added security.

Impact: The customized slides elevated the visual appeal of the display cabinets and improved customer interaction with the merchandise. The smooth operation and added security features enhanced the product displays’ functionality and safety.

These case studies underscore the importance of customized drawer slides in meeting the unique demands of different industries. By addressing specific challenges with tailored solutions, companies can enhance efficiency, functionality, and user satisfaction, ultimately contributing to their competitive advantage and success.

Conclusion

In conclusion, the strategic customization of drawer slides offers a powerful avenue for manufacturers to significantly boost their products’ functionality, efficiency, and overall performance. Businesses can craft drawer slides that meet and exceed their specific operational requirements by meticulously selecting the appropriate materials, optimizing size and load capacity, carefully choosing mounting options, and incorporating specialized features.

This approach to customization enables manufacturers to address the unique challenges and constraints of their applications, ensuring that every aspect of the drawer slide is engineered for optimal performance. Whether achieving smoother operation with soft-close mechanisms, enhancing user experience with push-to-open functionality, or ensuring security with integrated locks, the possibilities for customization are vast and varied.

Moreover, the benefits of customizing drawer slides extend beyond immediate product design and user satisfaction improvements. Tailored solutions can lead to greater efficiency in production and use, reduce maintenance and replacement costs over time, and even contribute to a more substantial brand reputation by delivering superior products to the market.

In an era where differentiation and functionality are critical to competitive advantage, investing in customized drawer slides is not just a matter of preference—it’s a strategic imperative. By embracing the potential for customization, manufacturers can unlock new levels of innovation and excellence in their products, setting new standards in their industry.

Embracing customization in drawer slides is, therefore, not just a step towards enhancing a single product component; it’s a move towards reimagining how products can be designed, manufactured, and experienced. As we look to the future, the role of customization in manufacturing will only grow, driven by the relentless pursuit of excellence and the endless possibilities that custom solutions provide.

Post time: Mar-05-2024

Mobile Phone

Mobile Phone E-mail

E-mail