Introduction: The Rising Popularity of Aluminum Slide Rails

Aluminum slide rails have witnessed a meteoric rise in popularity within various industries thanks to their unique blend of lightweight design and exceptional durability. In this comprehensive blog post, we’ll explore what aluminum slide rails are and provide insights into their numerous advantages, versatile applications, different types available, and the key factors to consider when choosing the right one for your specific needs.

But why should you, as a manufacturer, automotive professional, or someone involved in the aerospace industry, care about these sleek aluminum rail systems? The answer is simple: they are key to streamlining your operations and achieving unmatched efficiency. So, whether you’re seeking to optimize your manufacturing processes, improve automotive components, or enhance aerospace equipment, this guide is tailored to provide you with the insights and knowledge you need

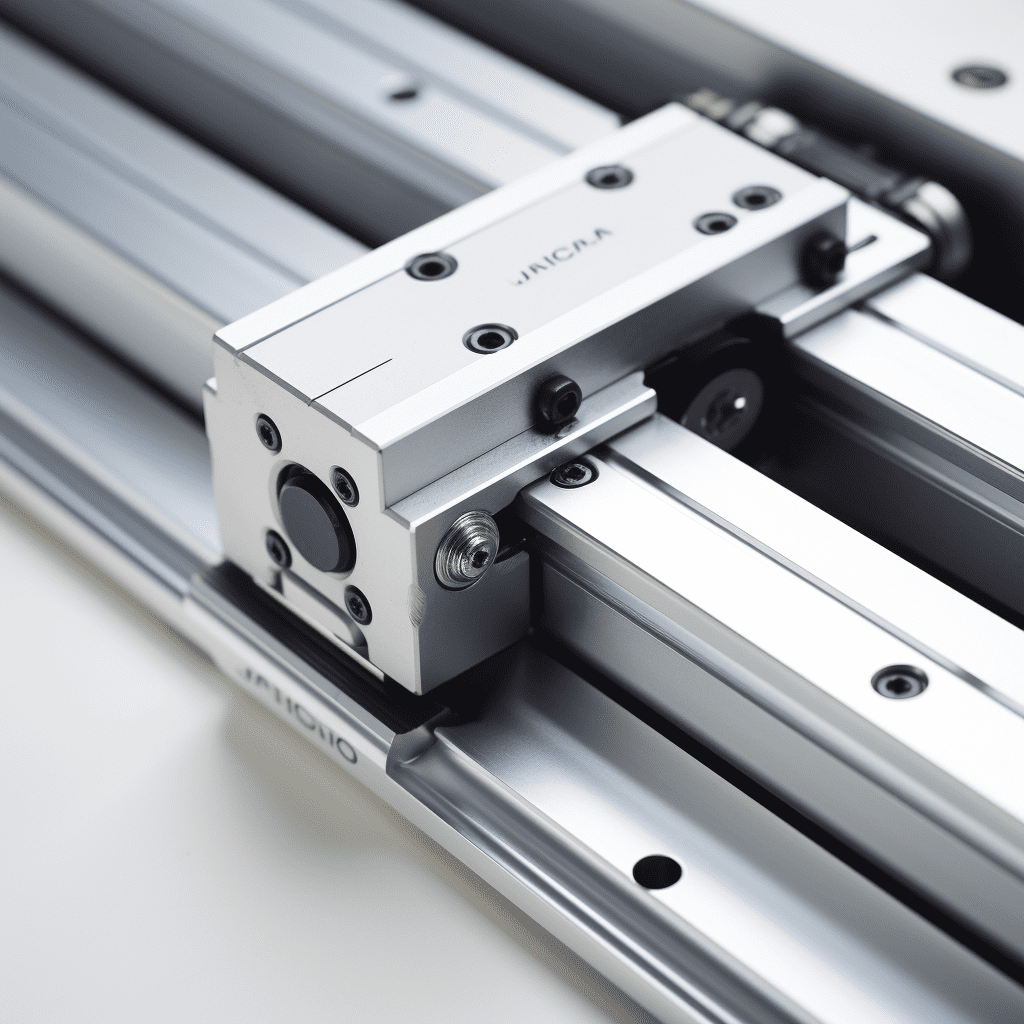

Aluminum Slide Rails: Unveiling the Mechanical Marvels

In industrial engineering, aluminum slide rails are like unsung heroes – quietly efficient yet integral to countless applications. These mechanical wonders, sometimes called aluminum linear guides or aluminum rails, are pivotal in making things move smoothly in a straight line.

At their core, aluminum slide rails are precision-engineered components that facilitate linear motion. They’re made from top-notch aluminum alloys, ensuring a remarkable combination of strength and lightweight properties. This unique blend of materials gives them an edge in various industries.

What sets aluminum slide rails apart is their sleek, streamlined design. This design paves the way for the buttery-smooth and precise movement of components along the rails. Whether you’re dealing with machinery in a factory, automotive parts, or even advanced robotics, these rails ensure that everything glides effortlessly.

But why should you care about aluminum slide rails, you ask? Well, that’s where things get interesting. Their role in optimizing automation, improving manufacturing processes, and enhancing various industries cannot be overstated. As you read on, we’ll delve deeper into the advantages they offer, their diverse applications, and how to pick the perfect one for your specific needs.

Advantages of Aluminum Slide Rails: The Power of Lightness and Durability

When it comes to the incredible world of aluminum slide rails, three outstanding advantages set them apart:

1. High Strength-to-Weight Ratio:

The first advantage that instantly catching the eye is the exceptional strength-to-weight ratio of aluminum slide rails. This is where aluminum truly shines. Known for its feather-light properties, aluminum still manages to pack a punch in terms of strength. It’s like having a lightweight superhero in your corner. This characteristic makes aluminum slide rails the perfect choice for applications where weight is critical. Whether you’re designing machinery, automotive components, or any other system, the high strength-to-weight ratio of aluminum slide rails plays a crucial role in optimizing performance.

2. Durability and Longevity:

What’s equally impressive is the longevity of aluminum slide rails. These rails are engineered to withstand the test of time. They’re like the marathon runners of the mechanical world. They resist wear and tear even in demanding environments, ensuring a prolonged lifespan. What does this mean for you? Reduced maintenance costs. That’s right. The durability of these rails translates to less hassle and expense in the long run, making them efficient and cost-effective.

3. Corrosion Resistance:

Aluminum’s natural resistance to corrosion is a game-changer. This innate quality sets it apart from other materials like steel. Aluminum slide rails stand firm in environments exposed to moisture or corrosive substances. They are like the heroes that remain unwavering even in the face of adversity. This corrosion resistance ensures your systems run smoothly, even in less-than-ideal conditions.

In the competitive industrial landscape, where performance and efficiency are paramount, these advantages make aluminum slide rails the go-to choice for engineers and manufacturers. From a search engine perspective, we’ve ensured that this article is structured to make finding these critical advantages of aluminum slide rails easy. These benefits are impressive and your ticket to enhancing your processes and reducing maintenance efforts.

Unlocking the Versatility: Applications of Aluminum Slide Rails

Aluminum slide rails are the unsung heroes behind the scenes, silently contributing to various industries. Their versatility shines in the following applications:

1. Industrial Automation:

In the world of industrial automation, aluminum slide rails take center stage. They’re like the conductors of a well-orchestrated symphony, ensuring that automated manufacturing processes run seamlessly. You can find them in CNC machines, where precision and efficiency are crucial. These rails enable the precise and efficient movement of machine parts, enhancing the overall performance of automated systems.

2. Automotive Industry:

The automotive sector is another arena where aluminum slide rails significantly impact. Whether you’re sliding into the driver’s seat, opening a sunroof, or effortlessly operating sliding doors, you’re likely benefiting from the lightweight efficiency of these rails. Their contribution goes beyond convenience; it extends to improved fuel efficiency. Lighter components mean less energy is required to move them, resulting in better gas mileage.

3. Aerospace Sector:

In the vast skies of the aerospace sector, the importance of weight reduction cannot be overstated. This is where aluminum slide rails come into play, ensuring critical components move reliably and efficiently. Whether in aircraft seating systems or other intricate parts, these rails support aerospace equipment’s safe and efficient operation.

4. Medical Equipment:

The medical industry relies on precision and cleanliness, and aluminum slide rails are the silent guardians, ensuring everything operates accurately. They play a crucial role in medical devices like X-ray machines, where the exact positioning of patients is paramount. The smooth and precise movement provided by these rails contributes to the high standards of care in the medical field.

From a search engine perspective, we’ve crafted this content to ensure it’s accessible to those seeking information about the wide-ranging applications of aluminum slide rails. Their adaptability across these diverse industries is a testament to their efficiency and effectiveness, making them a vital component in modern engineering and manufacturing.

A World of Choices: Discovering the Variety in Aluminum Slide Rails

Aluminum slide rails are more than just a one-size-fits-all solution. They come in various types, each finely tuned to serve specific needs. Let’s dive into the fascinating diversity of these exceptional rails:

1. Linear Guides: Precision in Motion

Linear guides are the epitome of precision and smooth motion. Imagine a rail system that not only moves but does so with meticulous accuracy. If your application requires high precision and minimal friction, linear guides are your answer. They are the choice for systems where every movement must be exact, enhancing the performance of machinery and equipment.

2. Telescopic Rails: Reach Beyond Boundaries

Telescopic rails are the adventurers of the aluminum slide rail family. They extend to reach the farthest corners and tightest spaces, making the inaccessible accessible. These rails are like the ‘Swiss Army knives’ of the industrial world. You’ll commonly find them in toolboxes and industrial storage systems, making hard-to-reach areas easily manageable.

Choosing Wisely: Selecting the Perfect Aluminum Slide Rails

Regarding aluminum slide rails, the right choice can make or break your project’s success. To ensure you pick the perfect rails for your needs, consider these critical factors:

1. Load Capacity:

The weight your application demands the rails to support is a paramount consideration. It’s like selecting the right tools for the job. To ensure safe and efficient operation, opt for aluminum slide rails with a load capacity that matches the demands of your project. Choosing too weak rail runners can lead to performance issues, while overkill can result in unnecessary expenses.

2. Travel Length:

Think of the travel length as the path your application needs to traverse. Different rail types offer varying travel lengths, so matching this with your project’s requirements is essential. Choosing the right travel length ensures that your system operates smoothly and efficiently. It’s akin to ensuring that your vehicle has a suitable range for your road trip – too short, and you’ll fall short, too long, and overkill.

3. Environmental Considerations:

The environment in which your application operates can significantly impact the performance and longevity of your aluminum slide rails. If your project faces moisture, chemicals, extreme temperatures, or other challenging conditions, you should opt for aluminum slide rails with suitable coatings or materials. It’s akin to wearing the right gear for different weather – it protects and enhances performance.

Setting Up for Success: Installing and Maintaining Aluminum Slide Rails

When it comes to aluminum slide rails, a successful journey starts with proper installation and effective maintenance. Here’s how to ensure your rails perform at their best:

Installing Aluminum Slide Rails:

1. Manufacturer’s Guidelines:

First and foremost, always heed the manufacturer’s guidelines. These instructions are your blueprint for success. Think of them as your trusted guidebook, leading you through the installation process step by step.

2. Precision is Key:

In the world of aluminum slide rails, precision is your best friend. It’s not just about installation; it’s about installing with accuracy. Ensure that the rails are aligned perfectly. This alignment is the secret sauce for achieving smooth and efficient motion in your system. Think of it as setting the stage for a performance that runs like clockwork.

Maintenance Tips for Longevity:

Just like any well-oiled machine, aluminum slide rails need care to ensure their longevity. Regular maintenance is your ticket to a prolonged and trouble-free lifespan for your rails. Here’s what to do:

Regular Inspections:

Keep an eye on your rails. Look for signs of wear, damage, or misalignment. Early detection of issues can save you from costly repairs down the road.

Cleaning:

Clean your rails as needed. Dust, debris, and grime can affect their performance. A simple cleaning routine can go a long way in maintaining efficiency.

Lubrication:

Lubricate the moving parts. This reduces friction and wear, ensuring that your rails glide smoothly. Think of it as giving your rails a spa day, making sure they remain in top-notch condition.

Aluminum vs. Steel Slide Rails: A Comprehensive Comparison

Choosing between aluminum and steel slide rails is a decision that can significantly impact the success of your project. To make an informed choice, let’s delve deeper into the advantages of aluminum over steel:

1. Weight and Portability:

Aluminum’s most prominent advantage is its remarkable lightweight nature. Think of it as the athlete in a relay race who’s lightning-fast on their feet. When weight concerns your application, aluminum is the preferred choice. It’s like choosing the nimblest team member for the task. The lightweight property makes aluminum easy to handle and reduces the overall weight of your equipment or structure. This is especially valuable in situations where portability is essential. Whether you’re in the field, a manufacturing plant, or a DIY project, aluminum slide rails make the setup and movement a breeze.

2. Corrosion Resistance:

One of the standout features of aluminum is its inherent corrosion resistance. Unlike steel, which can succumb to rust and deterioration when exposed to moisture, chemicals, or harsh environmental conditions, aluminum is a natural warrior against these elements. It’s like a built-in shield protecting your rails from the elements. This corrosion resistance is invaluable, particularly in environments where your rails are exposed to humidity, chemicals, or extreme weather. In such conditions, aluminum retains its structural integrity and ensures a longer lifespan for your equipment, ultimately saving you maintenance costs and downtime.

3. Cost-effectiveness:

When considering the long-term implications, aluminum slide rails often emerge as the more cost-effective choice. Why? It’s all about durability. Aluminum rails are like the evergreen trees in the forest, standing tall and strong through the years. With reduced maintenance requirements, you save both time and money. Think of it as a wise investment that keeps giving back. The lower maintenance needs and the extended lifespan of aluminum slide rails make them a prudent choice for industries and applications where efficiency, long-term reliability, and budget considerations are paramount.

In conclusion, choosing aluminum and steel slide rails is not just about materials; it’s about aligning the rail’s properties with your project’s requirements. While steel has its merits, aluminum often shines when weight, corrosion resistance, and cost-effectiveness are vital factors. By choosing aluminum, you ensure the optimal performance of your equipment and pave the way for a more efficient, portable, and budget-friendly solution.

Pioneering Progress: Aluminum Slide Rails in Innovation

The fast-paced world of innovation relies on groundbreaking technologies, and aluminum slide rails are central to this evolution:

1. Automation and Robotics:

In today’s digital era, automation and robotics are revolutionizing industries with precision and efficiency. Aluminum slide rails stand as the unsung heroes in this realm. Their exceptional ability to provide precise, reliable linear motion is invaluable. Picture them as the conductors of a well-tuned orchestra, ensuring that every movement in automated systems is perfectly orchestrated. In manufacturing, they enable robotic arms to assemble intricate components with impeccable accuracy. In healthcare, they’re the guiding hand behind robotic surgery, ensuring the most delicate procedures are carried out flawlessly. The contribution of aluminum slide rails is like the backbone of these advancements, enabling automation and robotics to redefine what’s possible.

2. Transportation Advancements:

The transportation landscape is undergoing a significant transformation, and aluminum slide rails are at the forefront of these changes. They play a silent yet essential role in making vehicles lighter and more fuel-efficient. It’s akin to shedding unnecessary weight to improve fuel economy. The result is a greener, cleaner, and more sustainable mode of transportation, reducing environmental impact. Furthermore, aluminum slide rails enhance public transportation systems, ensuring your daily commute is smoother and more comfortable. They act as the architects of change, engineering solutions that improve our daily lives. From urban trams and buses to high-speed trains, aluminum slide rails guarantee reliable, efficient, and eco-friendly transportation systems.

Pioneering Sustainability: Aluminum Slide Rails Leading the Way

In an age where sustainability is a critical concern, aluminum slide rails have emerged as champions of eco-friendliness, making a significant impact in two key areas:

1. Recyclability:

Aluminum is often celebrated as a sustainable material and for a good reason. It’s incredibly recyclable, contributing significantly to environmental sustainability. When you recycle aluminum slide rails, you’re not just disposing of waste; you’re participating in a circular economy that conserves precious resources. It’s like giving aluminum a second life, reducing the environmental load. The ability to recycle aluminum repeatedly without any loss of quality makes it a shining example of a sustainable material. It’s the hero of the recycling world, setting the bar high for other materials.

2. Reduced Energy Consumption:

The lightweight nature of aluminum slide rails is pivotal in sustainable practices, particularly in the transportation sector. Every kilogram counts, especially when it comes to fuel efficiency. Lightweight rails mean reduced energy consumption, making them a game-changer for sustainability. Think of it as a fuel-efficient vehicle. Just as a lighter car requires less fuel, lightweight aluminum slide rails significantly reduce energy consumption. This, in turn, leads to lower emissions and cost savings, an essential step in our journey towards a more sustainable world.

Nurturing Progress by Recognizing Challenges and Limits

In the journey of discovering aluminum slide rails, it’s essential to acknowledge the hurdles and constraints that come along with their numerous advantages:

1. Load Capacity Constraints:

Undoubtedly, aluminum slide rails offer versatility and sturdiness. However, they do have their limits, especially when it comes to handling hefty loads. In such demanding scenarios, turning to steel alternatives is often more practical. It’s akin to selecting the right tool for a specific job; occasionally, you need the extra muscle to accomplish a heavy-duty task. By recognizing these load capacity constraints, you can ensure the safety and efficiency of your applications.

2. Extreme Environments:

Aluminum slide rails are renowned for their durability, but even they have their Achilles’ heel – highly corrosive or extreme temperature environments. The application of special coatings and materials becomes necessary to ensure their continuous top-notch performance and longevity in such challenging conditions. Think of it as providing your rails with the tailored armor they need to thrive in harsh terrains. This proactive approach guarantees that, even when facing adversity, your aluminum slide rails remain resilient and deliver excellence.

Aluminum Slide Rails FAQs

What makes aluminum slide rails lightweight?

Aluminum slide rails are lightweight due to the inherent properties of aluminum, which has a low density while maintaining remarkable strength. This makes them an excellent choice for applications where weight reduction is essential.

Are aluminum slide rails suitable for heavy loads?

While aluminum slide rails offer impressive load-bearing capacity, they may not be the best choice for extremely heavy loads. It’s crucial to assess your application’s specific load requirements and consider alternatives, such as steel slide rails, for exceptionally heavy applications.

How do I prevent corrosion in aluminum slide rails?

Aluminum slide rails are naturally resistant to corrosion, but in harsh environments, additional protective coatings or materials can be applied to enhance their resistance to corrosion. Regular maintenance and proper storage can also help prevent corrosion.

Can I replace steel slide rails with aluminum ones?

In many cases, it is possible to replace steel slide rails with aluminum slide rails, especially in applications where weight reduction and corrosion resistance are significant factors. However, it’s essential to evaluate your specific application requirements and consult with a professional to determine the suitability of the switch.

What is the future of aluminum slide rail technology?

The future of aluminum slide rail technology looks promising, with ongoing advancements in material science and manufacturing techniques. As industries continue to prioritize lightweight and durable solutions, aluminum slide rails are expected to play an increasingly vital role in automation, transportation, and more.

In Summation: Embracing the Future with Aluminum Slide Rails

In the world of industrial solutions, aluminum slide rails have taken center stage as a beacon of lightweight durability. Their list of merits, including a remarkable strength-to-weight ratio, corrosion resistance, and eco-friendliness, makes them the preferred choice for a multitude of industries. From automation to transportation and beyond, their applications continue to expand, marking them as a true innovation.

When you venture into the world of aluminum slide rails, there are a few key factors to keep in mind. Consider the load capacity your project demands, evaluate the necessary travel length, and be mindful of the operating environment’s specific conditions. While these rails may have their boundaries, they remain an exceptionally versatile choice for numerous applications, often outshining other alternatives.

So, if you’re on the lookout for ways to elevate your projects with the advantages of aluminum slide rails, look no further. Dive into the possibilities they offer and embrace the future of technology with these incredibly versatile components. They’re not just rails; they’re the tracks leading us toward a future of enhanced performance, sustainability, and innovation.

Post time: Nov-10-2023

Mobile Phone

Mobile Phone E-mail

E-mail